Do you want to know what an impact driver is and how it can make your DIY projects easier and faster? Then this guide is perfect for you!

Discover the immense power of an impact driver and how it can help you tackle various tasks with ease.

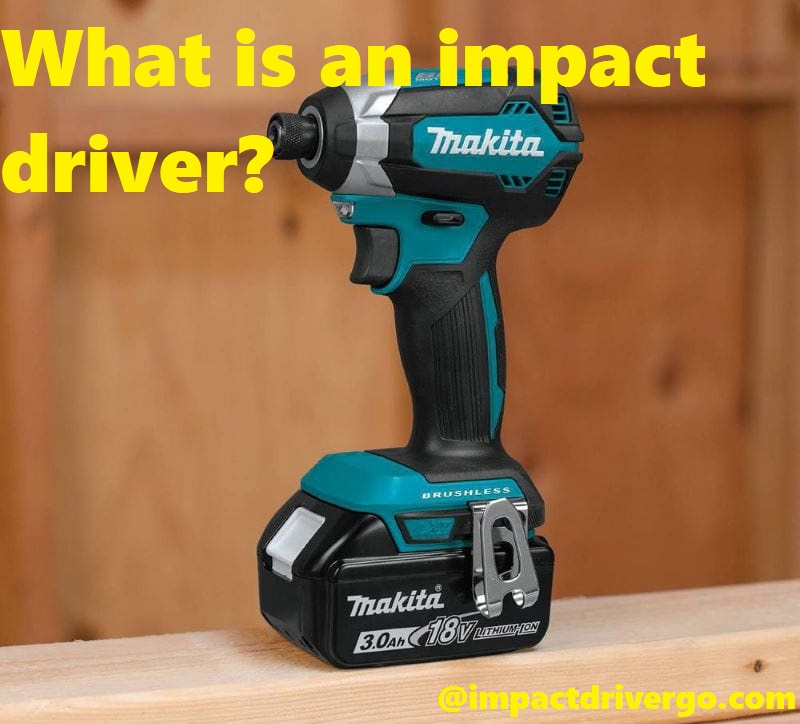

An impact driver is one of the most powerful tools in a power tool user’s arsenal. Combining its high torque and relatively light weight, it makes quick work of driving screws, bolts and other fasteners into even the toughest materials.

In this guide, we will cover everything you need to know about impact drivers, including what they are, how to use them safely, which accessories to use with them and more. With this information you should be able to make an informed decision as to whether an impact driver is right for your project needs.

Explanation of what an impact driver is

An impact driver is a power tool similar to a drill, but with a few major differences. Impact drivers use rotational forces to drive screws in and out of materials, helping you quickly and easily complete projects around the house. In addition to its rotational force, it also offers an additional striking force from the hammer action of a piston mechanism inside the motor that helps drive screws into tough materials like hardwoods easily. The combination of rotational force and striking force make it one of the most powerful tools in a standard home workshop.

Impact drivers are often used for driving self-tapping screws (often known as wood screws) as well as for removing rusted or stripped bolts and screws. Impact drivers typically offer higher torque than regular drills, allowing you to complete most driving or removing tasks faster than ever before! Impact drivers feature adjustable chucks that enable quick bit changes, so you can switch between different tasks quickly and efficiently.

Using an impact driver requires special safety precautions like eye protection and hearing protection. Due to their powerful torque capabilities, they should never be used without proper safety gear since objects can be thrown violently if not secured properly with the necessary accessories.

Importance of having an impact driver

An impact driver is a tool that is used to generate more torque than screwdrivers, making it an ideal choice for high-torque projects. This type of power tool has a variety of uses and benefits that can greatly reduce the amount of time needed to complete a project.

Having an impact driver can make any DIYer or professional more efficient and also reduce the risk of injury due to over exertion or strain caused by manual tools such as regular screwdrivers. The ability to quickly and easily drive screws with one hand allows for faster completion of projects. Working with an impact driver also reduces fatigue due to its compact design and weight, which makes it easier to use for long periods of time.

For outdoor projects, such as building decks or installing fencing, having an impact driver comes in handy as it can be used on screws that require pressure or fastening lag bolts into wood beams or posts securely without stripping the threading. Additionally, it can help keep hands clean because there is no need for additional lubrication such as oil when using this type of tool.

Impact Driver vs. Drill

The impact driver is designed specifically for driving fasteners such as screws, nuts and bolts. It works by providing a hammering force to the drive bit as it turns. This force puts considerably more torque on the bit than a standard cordless screwdriver or drill can provide. The result is that you can get through tougher materials such as dense woods or heavy-duty metals without having to apply much effort. It’s also useful when working in tight spaces, such as between two pieces of framing lumber or joining slotted strip boards together.

While a cordless screwdriver or drill can handle lighter jobs, an impact driver is the tool of choice for heavy duty applications. With its added power and torque, it’s able to drive thick screws into tough materials effortlessly. A drill can often slip when driving thicker screws making it difficult to create accurate holes and secure fasteners properly; but an impact driver will easily do the job every time without slipping up once. Additionally, while not quite as accurate as a drill, impact drivers are still able to do precision work within narrow spaces with very little deviation in accuracy compared to drillsor screwdrivers.

Differences between an impact driver and a drill

Impact drivers and drill drivers are both essential tools for any DIYer or home improvement professional, but they’re used for different purposes. While both tools use similar mechanisms to rotate a bit, the impact driver uses more force while drilling. Impact driver bits do not cam-out, so they remain gripped and can be used to drive self-tapping screws and other fasteners with greater precision than a drill.

Impact drivers also create greater torque when driving screws compared to a drill driver, making them great for tasks such as driving lag bolts into wood. Impact drivers also tend to be smaller in size than drills, making them easier to handle in tight spaces such as behind kitchen cabinets or in corners of closets. They’re even great for basic tasks such as assembling furniture or hanging sheets of drywall.

Overall, an impact driver is best suited for applications where high torque with lower speed is desired, while a drill is typically used for drilling holes and driving fasteners with low torque at higher speeds. Both tools are essential in any toolbox and serve different purposes when it comes to tackling large projects around the house.

When to use an impact driver vs. a drill

When it comes to deciding between an impact driver vs. a drill for your task, you’ll want to consider the kind of job you’re working on and the materials you’ll be driving screws into. In general, an impact driver is much more suitable for heavier jobs that require a lot of torque such as driving large screws or bolts into metal or wood, as well as jobs where there is a lot of resistance, such as driving screws into hard plastic or concrete.

Impact drivers also have the advantage of being able to handle thicker and longer screws than drills can handle. Additionally, impact drivers are much more suited to loosening large number of fasteners quickly that have been driven in tightly due to its hammering action which delivers high levels of torque without requiring the user to put any pressure on the tool itself. On the other hand, drills excel at attaching materials such as plastic or metal sheets and performing certain types (including delicately precise types) of drilling operations where complete accuracy is required.

How to Use an Impact Driver

An impact driver is a powerful hand-held tool used to tighten and loosen specialty fasteners such as screws, bolts, and lag screws. The tool works by converting the rotational force of its motor into a high level of consistent torque, which is then transferred directly to the screw head. It utilizes a hammering action to quickly break through even the toughest material, making it ideal for any job that requires speed and precision.

The following steps provide an overview on how to use a professional grade impact driver:

- Familiarize yourself with the device – The first thing you need to do before using an impact driver is familiarizing yourself with its components and functions. Read through your manual or watch online tutorials on how each part operates or interacts with other parts. Pay special attention to safety warnings in order for propel usage of the device without damaging property or harming yourself or others around you.

- Select your bits – Make sure that your chosen bit matches your fastener type so that it can deliver maximum performance on your project. Generally speaking, Phillips head screws require a Phillips bit and slotted screws require a slotted bit (also known as flathead bits). Additionally, larger bits require more power than smaller ones; therefore use them accordingly in order not over-torque the fasteners which can lead to damaging the device itself as well as stripping them prematurely.

3 Set Your Clutch – The clutch of an impact driver helps you adjust power settings based on the size of your fastener and allow more control while driving in smaller spaces by disengaging when certain pressure has been reached preventing over-torqueing or stripping fasteners/materials further ahead in line (such as if multiple screws are present). To adjust cluches when necessary,just rotate knob on side of tool until either pressure mark that’s shown matches up with arrow position indicated on clutch plate next to it depending on task ahead (generally speaking lighter pressure corresponds softer materials like drywall whereas thicker materials require heavier torque).

4 Adjust Hammer Settings – Adjustable hammers offer plenty versatility allowing users set specific depth points for impacting into given material by simply turning bottom knob accordingly; this feature allows finely tuned tasks with minimal possibility missteps along way due craftsmanship’s congruency between preset settings inputted prior onto device itself! As such depending size of screw along type material/thickness being drilled through one may need adjust multiple throws settings by slowly letting downward pressure gauge build upon itself slowly until desired point arrived at then proceed moving forward normally afterwards per usual again!

Preparing the Work Area

To ensure safety, properly prepare the work area before beginning your project. Start by making sure that both the working area and your tools are clean and free of debris. Be sure you have ample space to work and to handle any project materials or items. Additionally, it’s important to wear the proper safety attire when using any power tool, including eye protection and leather gloves when necessary.

Be sure you have all of your hand-operated tools near you before powering up your impact driver so that you don’t need to fetch materials while in use. Make sure that power cords and other wires are tucked away so they cannot become a dangerous tripping hazard or get wrapped up in moving parts of the tool during operation.

Loading the Impact Driver with a Bit

Loading the impact driver with a drill bit or other accessory is typically very simple. Most brands provide an ergonomic handle that makes it easy to grip and manipulate the bit. Once you have identified the appropriate size, angle, or shape for your particular task, insert it into the chuck on the impact driver’s shaft. If the bit has a flat-sided shank, you may need to use a special adaptor to ensure proper loading.

Once the bit is secured in place, be sure to test its functionality. You could do this by pressing down lightly on any available material and checking for proper attachment. If everything seems secure and functioning properly, tighten the chuck by twisting clockwise until snug.

Maintenance and Safety

Caring for your impact driver will ensure a long life of service. Make sure to read and follow the manufacturer’s instructions for maintenance and safety to make sure you use your tool correctly. We recommend annual inspections of the tool, air filter and hoses. Always maintain proper lubrication of moving parts, such as gears and bit sockets, to reduce wear. Replace any worn out components as required, such as grinding wheels or drill bits.

Take safety precautions when using your impact driver; this type of tool is not intended for light duty use. Wear protection from debris being kicked around from drilling or grinding, such as safety glasses and hearing protection. Make sure the work surface is secure and that all objects are at least 5 feet from the working area before starting your project so that you can maintain control over the bit or grinding wheel without any interference from nearby objects.

Maintenance Tips

Regular maintenance of an impact driver is essential for it to function properly. There are several ways to ensure that your impact driver remains in good condition and at peak performance. Here are a few tips:

- Clean the exterior of the tool after every use. This will help prevent dirt buildup and damage to the internal components.

- Inspect the cord for any signs of wear or damage before each use. If necessary, replace the cord with an approved one from the manufacturer.

- Tighten all screws and bolts on a regular basis. Loose connections can cause issues such as motor failure or decreased power output over time.

- Change out worn or damaged parts according to your tool’s manual instructions, even if they are not affecting its performance in a significant way. Doing so now may prevent bigger issues later on.

- Apply motor oil onto moving parts and other surfaces as instructed in your tool’s user manual to reduce friction between parts and increase their lifespan.

Following these steps will keep your impact driver functioning like new for years to come!

Safety Tips

Using an impact driver is safe as long as you follow certain guidelines. Before using one, always make sure you read and understand the safety warnings issued by the manufacturer. Wear protective gear such as safety goggles, a dust mask, earplugs or muffs, and steel-toe boots. Unplug the tool when loading bits or changing accessories. Make sure to use only impact-rated bits for these tools — regular bits may break if used in an impact driver.

Finally, keep your body away from the line of fire when drilling; it is not advisable to straddle the workpiece with your legs or to put any part of your body directly over where a hole will be drilled.

Conclusion

In conclusion, an impact driver is a power tool that operates on the principle of applying torque to fasteners such as screws and nuts. By using high-torque energy pulses, it drives screws into materials with ease. The driver can be used to assemble furniture, hang pictures, or tighten bolts — all much easier than manually doing it.

Impact drivers are also lighter and more compact than standard drivers, making them ideal for working in tight spaces. Additionally, they generate less noise and vibration than regular drills. Finally, they are affordable and easily available at most hardware stores.

An impact driver is the perfect tool for any do-it-yourselfer looking to save time and take on projects more efficiently.

FAQs

What do you use a impact driver for?

An impact driver is used for driving screws and bolts into tough materials.

What’s the difference between a drill and impact driver?

A drill is used for drilling holes, while an impact driver is used for driving screws and bolts.

Do I really need an impact driver?

It depends on the type of work you do. If you frequently work with tough materials and drive a lot of screws and bolts, an impact driver can be very useful.

Is an impact driver the same as a hammer drill?

No, an impact driver and a hammer drill are two different tools. A hammer drill is used for drilling into hard materials like concrete, while an impact driver is used for driving screws and bolts.

Can I use a drill as an impact driver?

No, a drill and an impact driver are two different tools with different functions.

Can you just use a impact driver to drill?

No, an impact driver is not designed for drilling holes.

When should you not use impact driver?

An impact driver should not be used for delicate or precision work, as it can be too powerful and cause damage.

Do impact drivers need special bits?

Yes, impact drivers require special bits that are designed to withstand the high torque and force generated by the tool.

Can I use impact driver to drill concrete?

No, an impact driver is not designed for drilling into hard materials like concrete.

What are the risks of using a impact driver?

The main risk of using an impact driver is the potential for injury if the tool is not used properly or if the user does not take proper safety precautions.

See Also-

- Best 12v impact driver

- Best battery impact driver

- Best bit set for impact driver

- Best brushless impact driver

- Best cordless impact driver